| Screen Shots | Tech Support | Donate |

| Program Features Html | PDF Documentation | Updates |

| Reloading Links | UNUSED | Follow Us on Facebook |

| Purchase Ballistic Basics | Download Now | Contact Us |

Ballistic Basics 14 ©

Now Free Donations Welcome

Interior and Exterior Ballistics and Reloading Software

The Most Complete Ballistics - Reloading Software Program Available Today

|

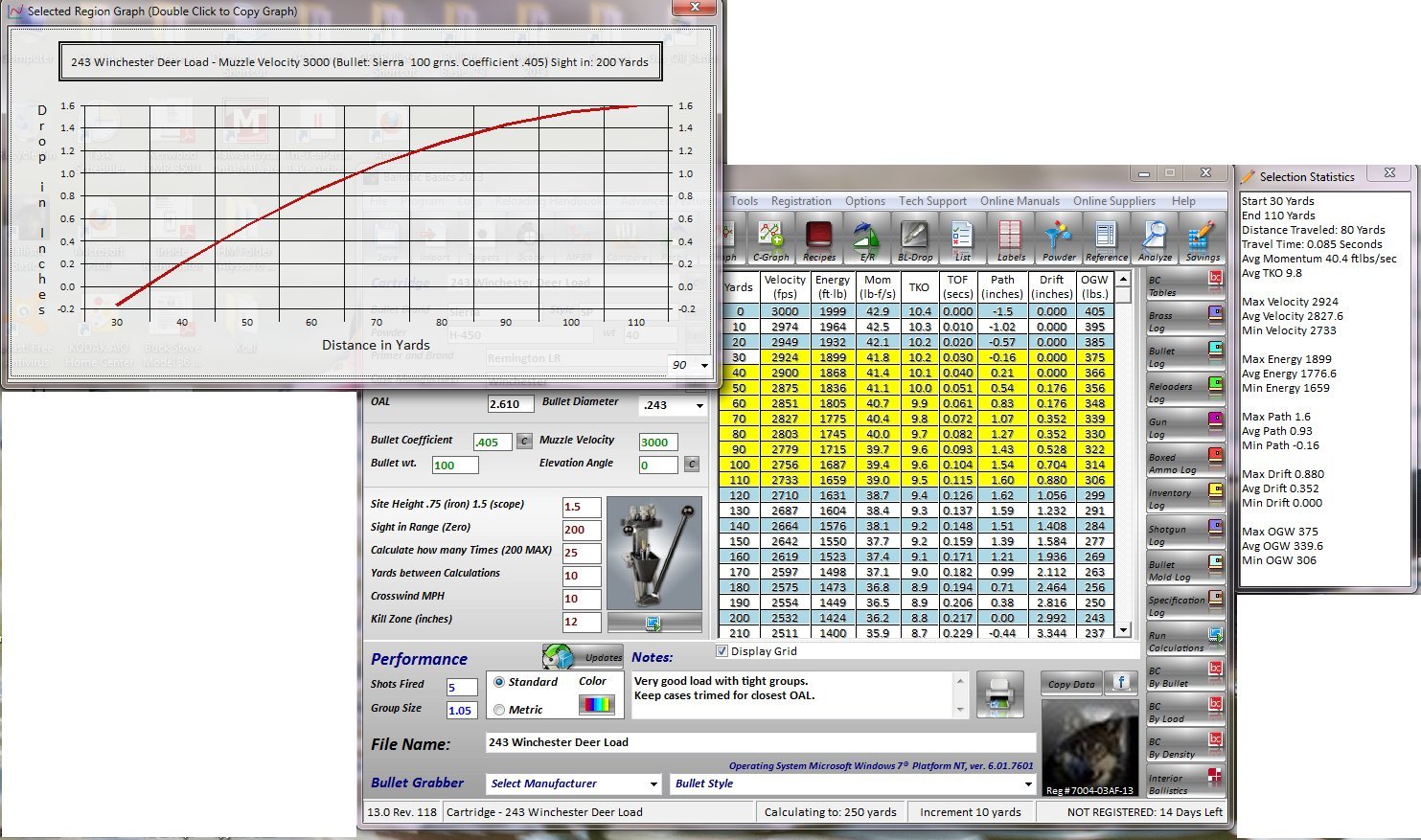

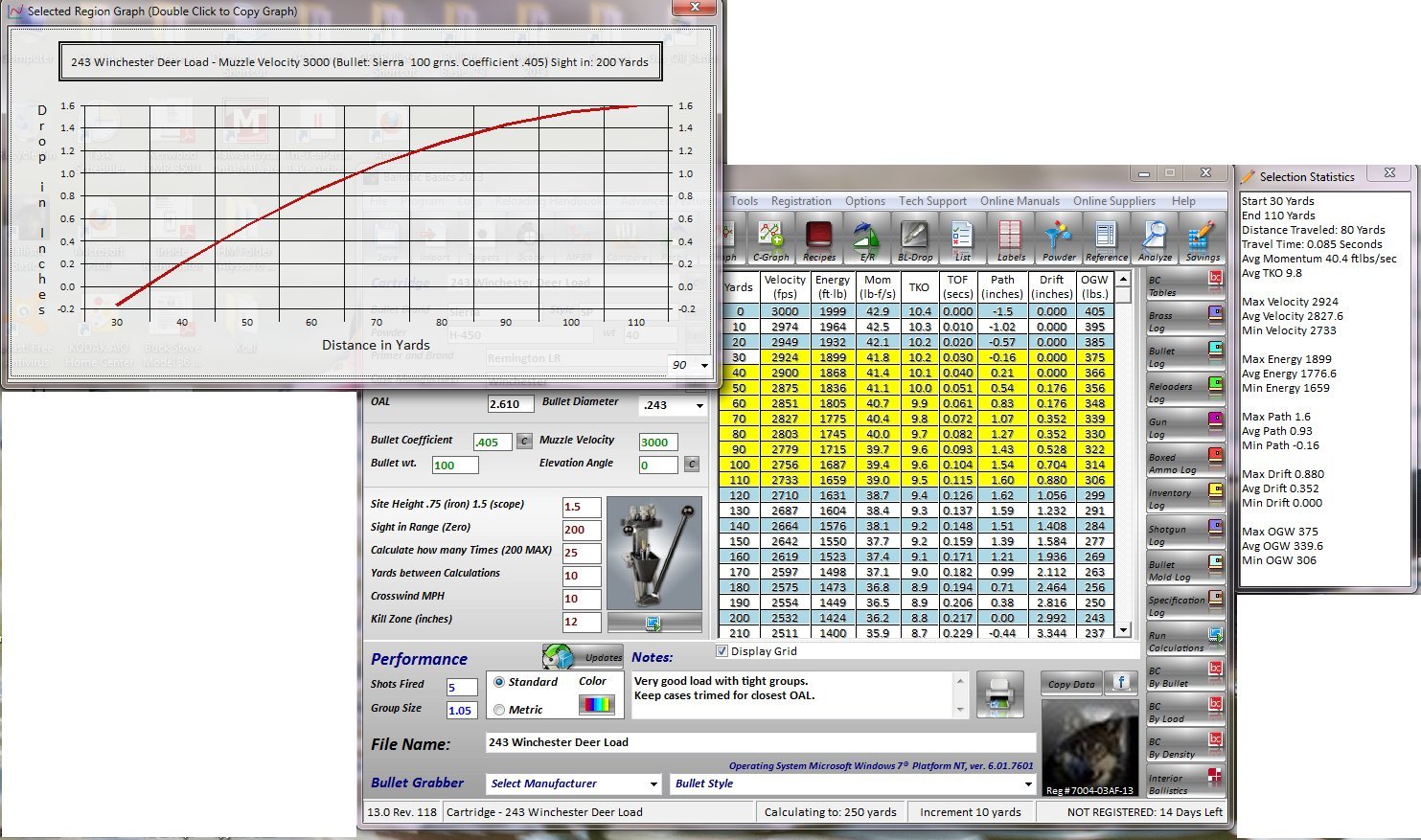

All in One Ballistics and Reloading Software. Calculating your ammunition's ballistics performance at all ranges is key to making successful shots on targets and in the field. Using Ballistic Basics allows you to both analyze and understand a wide variety of ballistics information. Ballistic Basics helps you to improve your accuracy and performance by designing the optimal load for your gun and by letting you visualize how different ammunition component combinations can affect your ability to hit a target... so no more relying on traditional ballistics tables. |

Features

You do not need to Donate to use the program. If you wish to Support the project click the button below you will be directed to my PayPal page *New for 14 *New for 14 Momentum at Range Expressed in units of "pound-seconds," momentum is a quantity of motion. Momentum is obtained by multiplying a bullets mass times its velocity. In many instances, momentum may be a better indicator of a bullet's potential than kinetic energy. TKO at Range A formulaic mathematical approach for evaluating the stopping power of hunting cartridges. The term "KO" is an acronym for "Knock Out." The Taylor KO Factor (TKOF) is a derived figure that allows hunters to compare bullets with respect to stopping power. The TKOF was developed by John "Pondoro" Taylor, a famous mid-20th century hunter and poacher of African big game. OGW at Range A formula developed by Edward A. Matunas to aid the hunter in selecting a cartridge/load appropriate to the game being hunted. We've all heard the arguments regarding kinetic energy versus momentum. Many authors have attempted to come up with an objective method of determining the "Killing power" of cartridge loadings. This is one that actually makes sense. It differentiates light bullet energies and heavy bullet energies with a degree of rationale. It produces numbers that most experienced hunters will find intuitively correct, expressed in a form that is convenient for the hunter, optimum game weight in pounds. The weight calculated assumes that occasionally you will take a hard quartering shot. If you push the envelope, the author suggests that you choose a load that will deliver a 25% heavier rating. This also assumes that the bullet chosen is constructed appropriately for the game being hunted. |

Current Visitor Count

Menu

|

|

| Endorsed By: United States Shooting.com and Forum supports and defends America's Second Amendment Rights through aggressive posting of newsworthy articles, blogs, and forum posts. United States Shooting.com's purpose and goal is to promote responsible firearms ownership, and to provide information to those who are interested in the shooting sports, hunting and conservation, and defending the Constitutional Rights of citizens of the United States. |

Click Here To Download Your 15 Day Trial There are no advertising banners or nag screens in the trial. |

Thinking about getting into reloading?

Here are the General Steps to Reloading: Rifle Cartridges

This Guide is Not Intended To Replace any Instructions from Your Reloading Press or Manuals

The first time you read a reloading manual, it will seem overwhelmingly technical and complicated.

Once you have loaded your first few batches of ammunition, it won't seem so overwhelming anymore.

Reloading is highly technical, requiring close attention to detail, but to simply reload safe and effective

ammunition, one need not overwhelm themselves with too many details. How complicated and technical you make

the reloading process has a lot to do with the type of ammunition you plan to load and what you intend to use it for.

Loading ammunition for long range Bench rest competition is very technical and complicated compared to simply

loading inexpensive ammunition to casually shoot at the range. Reloading rifle cartridges on a single stage

press is actually a pretty simple process.

- Case Preparation

When most newcomers think of reloading, they immediately think of charging cases with powder and seating bullets.

These are actually the final steps in the process, and most of the time spent reloading is actually spent on case

preparation. Properly cleaned and prepped cases are the foundation of good ammunition. If you skip steps in the case

preparation process, you can't make up for them later. If you plan on being very meticulous with your powder measuring

and bullet seating, you should be meticulous in your case preparation as well. Here, we will assume that you are starting

out with cases that have been fired, rather than new brass. The steps are the same for new brass except for the fact that

new brass need not be cleaned.

An important part of reloading safety is case inspection. Cases do wear out over time, and it is important to discard

cases that have reached the end of their life span or have been damaged. Make constant case inspection an integral

part of your reloading habits. After every step of the reloading process, inspect your cases both visually and by feel to

insure that they are still in good condition and safe to use. Any cases that seem suspect or that look out of the ordinary

should be culled from the batch. The most important inspection comes after the cases have been cleaned and sized.

Clean cases will show cracks and other damage more clearly, while case length measurements should be checked after sizing

to make sure that cases haven't stretched beyond safe limits. Cases that are near the end of their lifespan and have become

brittle often crack during re sizing.

- Cleaning

The first step in preparing fired cases for reloading is cleaning. The firing process leaves cases with a coating of sooty

residue both inside the case and on the outside, particularly around the neck. The easiest way to clean cases is in a vibratory

case cleaner or tumbler. Placed into the tumbler with media and left to run for several hours, cases will come out clean,

shiny and bright. The media will also somewhat clean the inside of the case, but not nearly as much as the outside. This is

fine as a little powder soot on the inside of the case won't have a negative effect on the cartridge. After tumbling, wipe off the

case to remove any media dust and check the inside of the case for any remaining media stuck inside. Case tumblers have been the

standard cleaning method for a while now, and for good reason. They are relatively inexpensive, yield excellent results, can clean large

numbers of cases at once, and are simple to operate.

Case tumblers aren't the only means of cleaning brass. Rifle cases that haven't been allowed to get too dirty can be cleaned by hand

with a rag or some steel wool. Typically, the hardest area to clean is the soot around the case neck, but a little scrubbing with

steel wool will take it right off. Brass polish on a rag works well too, but can be time consuming. If you do choose to use brass

polish, be sure to use one intended for cartridge cases as common brass polishes often contain ammonia which can weaken cases over time.

Relatively new on the market are ultrasonic cleaners designed to clean cartridge cases. Ultrasonic cleaning has been around for a

long time for cleaning jewelry or other delicate items, and recently it has been adapted for use by reloader's. One advantage to

ultrasonic cleaning is that it cleans the interior of cases very well too. Whether this has a beneficial affect on accuracy remains to

be seen, but it certainly looks nice. If brass is deprimed before ultrasonic cleaning, the primer pockets will get very clean as well.

Cleaning results from ultrasonic cleaners are highly dependent on the solution being used. Commercial cleaning solutions like that from

Hornady are somewhat expensive, which many reloader's find a major drawback to ultrasonic cleaners. Others have developed a variety of

home brewed recipes that seem to work well. As with any "wet" case cleaning method, the cases must be thoroughly dried before they are

ready to be sized and loaded.

Another way to clean cases is to simply wash them. A variety of recipes for brass washing solutions can be found on the internet

with regular dishwashing soap and water appearing to be the most popular. Washing cases works pretty well, but it requires more

labor to achieve good results. Cases need to be agitated quite a bit to get good results, and the soot around the neck often remains, requiring

hand wiping to get it off. Again, cases that are washed in any liquid solution will need to be thoroughly dried before proceeding with

the reloading process.

The final step of the cleaning process that should be completed before sizing is to brush out the case mouth.

Case mouths should be brushed out with either a nylon case neck brush, or a bronze bore brush of the same caliber as the cases.

Brushing out the case necks helps to remove any remaining carbon deposits which reduces wear on the sizing button of your die.

Clean case necks also promote consistent neck tension and bullet release.

- Sizing

Once cases have been cleaned and inspected, the next step is to resize the cases so that they will fit into the chamber of your firearm.

The simplest and most common way to size is full length sizing with the use of a standard full length die. A full length sizing die will

return the case to its original SAAMI specified dimensions for the caliber. Full length sizing ensures that your cartridges will reliably

chamber in any rifle of that caliber with a properly sized chamber.

Before sizing, it is necessary to lubricate the cases so that they can run smoothly in and out of the die. The only time that lubrication

isn't necessary is when pistol cases are being sized with the use of a carbide die. The method by which you apply lubricant to your cases

varies by lubricant type. Spray lubes are simple to use as they are simply sprayed onto the case and allowed to dry. Wipe on case lubes

such as Imperial die wax are also simple to use as they are simply rubbed onto the case with your fingers. Liquid case lubes are applied

through the use of a case lube pad. To use a lube pad, first apply a small amount of lubricant to the pad, and then roll the cases to be

lubricated across the pad applying slight downward pressure as the cases roll across the pad. Whichever type of case lube you choose, only

apply it to the body of the case, keeping it away from the neck/shoulder area. Excessive lubricant applied to the shoulder can result in

dents in the case at the shoulder. If you do get dents, don't worry as they will be ironed out during the next firing of the case, but reduce

the amount of lube you are putting on the cases. It is a good idea to also lightly lubricate the inside of your case necks. Lubing the inside

of the neck of every case is unnecessary, so simply wet a q-tip with some case lubricant and run it around the inside of every fifth case neck.

This will lube the case as well as lightly lubricate the sizing button of the die.

Once your cases are lubed, you can begin sizing them. First, be sure that the die is clean inside. New dies should be cleaned with gun cleaning

solvent prior to being used. Periodically disassembling and cleaning dies is a good idea as it prevents any dust, dirt, or case lube build up from

clogging and negatively affecting the functioning of the die. To properly set up your full length sizing die in your press, first loosen and back

up the lock ring on the die. Next, raise the ram of your press all the way up and let it stay up. Screw the die into the press until the bottom

of the die makes firm contact with the shell holder in the ram. Then, lower the ram and turn the die down another 1/4 turn further into the press.

You want enough tension between the die and the shell holder to take any "slack" out of the linkages of the press, but not so much that you are

putting undue pressure and wear on your press. This adjustment is best made by feel, so try screwing the die in just a little bit past the point

contact with the shell holder is made. You will be able to feel the point at which everything is tight enough and all the slack is out of the press.

This doesn't require much force and pressure, just a little bit more right at the end of the ram stroke. Tighten and secure the lock ring so that

the setting will remain the same. Adjust the decapping rod so that it extends out the bottom of the die approximately 1/8 to 1/4 of an inch.

The decapping rod can be adjusted at any time if it fails to fully eject spent primers during the sizing process. Don't extend the decapping rod too

far as you do not want the sizing button to contact the web of the case. Ideally you want the decapping pin to extend just far enough to eject

primers, but no further.

Now that your cases are lubed and your die is properly set up, it is time to size your cases. Place a case into the shell holder and run it up into

the die using a steady, even stroke. Sometimes, the case gets a little out of alignment, and the case mouth or shoulder will run into the bottom of the die.

If this happens, simply realign the case with your fingers and gently guide it into the die. You will feel the body of the case make contact with the

die and begin to be resized. This is the point at which you will begin to feel friction and will have to apply slightly more pressure.

The linkage in the press provides plenty of leverage, so you really shouldn't have to push down on the operating arm very hard. If you are experiencing

a lot of friction at this point and the case seems to be binding, back it out and apply more lube to the case along the body. A properly lubed case

will slide into and out of the die easily. As the case moves up into the die, the body will be sized and the last thing you will feel on the upstroke is

the decapping rod pushing the spent primer out of the bottom of the case. Once you have run the case all the way into the die, and the spent primer has

been ejected, pause for a moment with the case run all the way into the die. Brass is used for cases as it has the unique ability to "spring back" to its

former shape. Pausing at the top of the stroke will help to insure that the brass is completely sized, and won't "spring back" as you draw it out of the die.

Begin the down stroke by pulling upwards on the press arm. The last thing you will feel is the neck expander being pulled back out of the neck.

Remove the case from the shell holder, wipe off the lubricant with a rag, and place it into the loading block.

As you are wiping the lubricant off of your cases, give them a close visual inspection. Look for any cracks in the case or signs of stretching ahead of

the case web. Also, look for any heavy ejector marks or other damage to the rim or head of the case. Crimp shut with pliers the mouth of any cases that

you plan to discard so that it is obvious you have deemed them unsafe and don't plan to use them for loading anymore. Sometimes cases can crack under the

force of being resized, so that is why it is a good idea to inspect them after they have been sized.

- Trimming

After full length sizing, measure your cases using a caliper. Make sure that the length is still under the SAAMI specified maximum length.

How often your cases will need to be trimmed is the result of several factors including, the shape of the case, the size of your chamber, how "hot"

your loads are, and the caliber of the cases. Some calibers stretch their cases quickly, while others hardly stretch at all. If any cases in a batch

need to be trimmed, trim the whole batch to keep them all uniform. If your cases need to be trimmed after sizing, trim them back to the proper length

following the manufacturer's instructions that came with your trimmer. After a case has been trimmed, the mouth of the case will need to be deburred

with a deburring tool. The deburring tool will remove the sharp edge from the outside of the case neck as well as chamfer the inside of the neck to

ease bullet insertion. To deburr the mouths of your cases that have been trimmed, run the deburring tool around both the inside and the outside of the

case necks several times until all sharp burrs have been removed.

- Priming

Once all of your cases are cleaned, sized, inspected, trimmed to the right length, and deburred, it is time for priming. Before priming it is a good idea

to clean out the carbon residue from your primer pockets. Cleaning primer pockets aids consistent primer seating and ignition. It is also a good time to

inspect your cases again and check to make sure there is no cleaning media lodged in the flash hole. A primer pocket brush or uninforming tool can be used

to scrape the residue from the primer pocket. A few quick turns of the brush in the primer pocket are all that it takes to get most of the residue out.

It isn't necessary to get the pockets completely clean, but scrubbing out most of the fouling is a good idea.

Priming and handling primers is one of the reloading operations that can be potentially dangerous. Primers are explosive, and handled improperly they can

be hazardous. Primers have to be forcefully crushed to cause them to ignite so one need not be too concerned. It is wise to always wear safety glasses

while reloading, particularly while priming and handling primers. The greatest danger associated with primers is having a large numbers of primers grouped

together out of their packages. One primer going off in close proximity to others will set off any primers close by. For this reason, and to minimize

handling, it is recommended to only take out as many primers as you need for the number of cases to be primed. Handling primers is also an opportunity to

unintentionally corrupt them with oil from your skin or other contaminants. This is another reason it is a good idea to minimize your handling of primers,

and only remove them from their original package when they are ready to be used.

No matter what type of tool you use, the priming process is basically the same. The case is held by a shell holder and a priming punch presses a new primer

into the primer pocket of the case. Primer seating depth is critical as primers that aren't seated deep enough can be dangerous as they may be prematurely

detonated by contact with the action, or they may not go off at all. Primers are actually modified slightly by the seating process. When a primer is

manufactured, it isn't completely sensitized as the anvil isn't fully compressed into the priming mixture. As primers are seated to the proper depth,

the anvil is pressed slightly deeper into the cup, lightly compressing the primer pellet. This sensitizes or arms the primer so that it will be ignited by

the blow of the firing pin. However, primers that are seated too deep are hazardous as the anvil may be pressed into the priming pellet too far making the

primer dangerously sensitive. Ideally, primers should be seated approximately .005" below flush with the case head. At this depth, they are sufficiently

deep to be safe and sensitized, but are not so deep as to be out of reach of the firing pin.

To prime a case, place a primer anvil side up into the priming tool. If you are using an automatically fed tool, follow the manufacturer's instructions

for loading primers into the feeding tray or tubes. Place a case into the shell holder and operate the arm with steady, deliberate force. Excessive force

should not be required to seat primers so don't push unnecessarily hard. Most press-mounted and hand-held priming tools incorporate some means of mechanical

stop that prevents primers from being seated too deep or crushed by the priming punch. Once the primer is seated, remove the case from the shell holder and

run your finger over the base to feel whether or not the primer is seated properly. If it isn't seated below flush, place it back into the shell holder and

seat the primer again to the proper depth. While you are priming cases, watch for any that seem too easy to seat as this is the sign of a loose primer pocket.

Loose primer pockets are an indication of a worn out case or a case that has been subjected to excessive pressure. Cases with loose primer pockets should be

discarded, as a loose pocket could allow gas to flow out the primer pocket causing bolt face erosion and potential harm to the shooter. Once you have

properly primed a case, place it in the loading block and finish the batch.

- Charging the Cases

Charging the cases with powder may be the most critical step in the reloading process. This is the step where you must pay absolute attention to what you

are doing as there is little room for error. At this point, you should already have a load picked out and your load data in front of you. If you are using a

new load, any new components, or a new firearm, start with the minimum recommended starting load for the powder and bullet you are loading. Whether you are

going to weigh each load, or use a powder measure, it is important to weigh the first several charges to be sure you have your powder measure set up properly.

Set your scale to weigh the right powder charge and weigh out the desired amount of powder. Place your powder funnel over the mouth of a case and pour in

your powder charge. Some powder granules may stick to the funnel due to static electricity. Lightly tap the case on the bench or gently poke the powder with

your finger to get it all to go down into the case. Once you have the case charged with powder, you can either immediately seat a bullet, or set the case

aside in the loading block and charge all of the cases in the batch.

- Bullet Seating

After your cases have been charged with powder, the final step in the cartridge loading process is to seat a bullet. To set up the bullet seating die, first

loosen and back up the die lock ring and back out the seater plug at the top of the die. Initially you want the seater plug backed out far enough that it

doesn't yet contact the bullet. Raise the ram of your press all the way up and screw in the seating die until the die just makes contact with the shell holder.

If you don't plan on crimping the case around the bullet (for most rifle reloading you won't) unscrew the die from three-quarters to one full turn away from

the shell holder. This will raise the die enough that the crimp ring won't make contact with the case. Tighten down the die lock ring to maintain the setting

you have just established. Now it is time to adjust the seating plug. The seating plug adjustment is how you control the seating depth of your bullets which

also controls Cartridge Overall Length or O.A.L.

Before you adjust your seating plug, it is necessary to decide what O.A.L. you plan to use. In the reloading manual you will see a cartridge diagram which

displays the S.A.A.M.I. established dimensions for the cartridge you are loading. This diagram will also list a maximum cartridge overall length. This length

has more to do with cartridges being able to fit into a variety of different magazines, and function properly in all action types than anything else.

After powder and bullet selection, the O.A.L. adjustment is a hand loader's best tool for improving the accuracy of a cartridge. O.A.L. can be adjusted to fit

your particular rifle. When you adjust O.A.L., you are changing the distance that the bullet has to "jump" before initially coming into contact with the

lands of the barrel. Every rifle has a "sweet spot" where it will shoot the tightest groups. This best O.A.L. will be different for different bullets, so a

little experimentation is necessary whenever you are changing loads. There are a few factors that must be considered that will affect how much you can adjust

your O.A.L. for your rifle. First of all, you do not want to seat a bullet so far out that it is actually jammed into the lands when you chamber a cartridge.

This can result in an increase in pressure as well as making rounds difficult to chamber. A cartridge that is too long may not fit into the magazine of your

rifle, or won't function reliably in the action. Bullets must be seated deeply enough that the cartridge neck can grip the bullet sufficiently. The general

rule of thumb is that a bullet should be seated at least as deep as its diameter for proper neck tension and alignment. Bullets that are seated too deeply

can also cause an increase in pressure. In general, don't seat the bullets any deeper than necessary, and don't seat them any longer than what will fit into

the magazine of your rifle. To find the ideal O.A.L. for your rifle will require testing several loads at various lengths to see which one your rifle likes

best. If you are just getting started, you have two options. You can either measure your rifle's "seating depth" or just use the recommended O.A.L. listed in your load data.

Once you have decided upon an O.A.L. to seat your bullets to, it is time to adjust the bullet seating plug in your die. This operation is best done with a

dummy round (no primer or powder), but it can be done with one of your cases that has been charged with powder. Begin by placing the case into the

shell holder and place a bullet into the neck of the case. You can't push it in with your fingers, but you can just barely get it started.

It helps to guide the bullet up into the die with your fingers as you raise the ram of your press. Run the ram all the way up so that the bullet and case

are up in the die. At this point the bullet hasn't been pushed into the case at all since the seating plug is backed all the way out. Begin screwing the

seating plug into the die until you feel it make firm contact with the bullet. Lower the ram, withdrawing the case and screw the seating plug into the die

a few turns. Run the case and bullet back up into the die and this time you will be able to feel the bullet being pushed into the case mouth. Again,

lower the ram, but this time remove the cartridge and measure its length with your calipers. From here on you will fine tune the depth by making small

adjustments to the plug and seating the bullet further into the case until you have reached your target O.A.L. Keep in mind that you can only push the

bullet further in and you cannot pull it back out unless you use a bullet puller. If you proceed slowly, measuring each time, you will be able to reach

your desired seating depth fairly easily. Once you have reached the right depth, tighten down the lock ring on the seating plug to maintain the setting.

This setting will only seat to the same O.A.L. with the bullet you set it up with. If you change bullets, you will have to adjust your seating plug

accordingly.

At this point, you have a finished cartridge. Give the round one last visual inspection and place it into your cartridge box for storage.

The next step will be to test your loads at the range to see how they perform.